Types of kilns for pottery and ceramics

Kilns are sealed vessels that generate high temperatures using fuel or energy. Any object heated in a kiln is said to have “fired.” Different materials can be burned in a variety of kiln types. Kilns are made especially for ceramics, metal clay, glass, and enamels besides that you can also bake your homemade pinch pots in you home based kilns.

This article explores the many kilns used to make pottery and ceramics. There are several different styles of pottery kilns. Ceramic kiln designs have also evolved throughout time.

Different Types of Kilns for pottery & ceramics

There are essentially two types of kilns utilized by modern potters. The heating system of the kiln is the first element. Some kilns are heated by electricity. Other kilns produce heat by burning fuel. These are referred to as fuel-burning kilns. Anything from wood to sawdust to natural gas to propane might be used as fuel. A kiln that burns energy heats itself utilizing a range of combustible fuels.

Another acknowledged difference in kiln types is that between intermittent and continuous kilns. Intermittent or periodic kilns comprise the majority of smaller kilns used by amateurs and lone potters. Ceramics are baked in these kilns and then removed after they have cooled.

In contrast, continuous kilns never stop burning. Once loaded, a mobile platform moves the items from one side of the kiln to the other. While the kiln is still hot, the pottery begins to cool as it comes out. When producing large amounts of ceramics, these kilns are more frequently employed in industrial or commercial contexts.

[Yellowbox]are kilns safe for home use: checkout here[/yellowbox]

The majority of electric kiln users are home and independent potters. But heating pottery in gas kilns is also a widely used technique. Additionally, gas kilns have been around longer than electric kilns. So let’s begin by studying gas kilns.

Gas Kilns

Natural gas or propane can both be used in gas kilns. For insulation, the kiln’s chamber is lined with fire bricks. The chamber is heated by burner openings at the foot of the kiln. Burner ports are essentially holes through which gas is ignited. Gas kilns employ either an updraft or a downdraft design.

Updraft kilns

In an updraft kiln, burner openings are often found on each side of the base. The chamber is heated by the gas flames that emanate from the kiln’s side. A “bag wall” in specific gas kilns is a partition between the flame and the pottery.

The bag wall is often constructed with combustible fire bricks that have been carelessly packed. The products are therefore shielded from flame contact and harm. To enable heat to enter the chamber, the bricks are placed with spaces between them.

Whether or not the kiln has bag walls, heat rises from the bottom to the top. The chamber is heated on the way. In updraft kilns, a flue is situated on the kiln’s roof. The heat, gases, and fumes created during firing are released via the top of the kiln.

During a fire, the base of the kiln draws a draft into the flue—consequently, updraft. You may control the draft’s intensity with a damper on the top of the chimney. If the damper is closed, the flow of the current is reduced.

When the damper is closed, less oxygen is pulled into the kiln. It also raises the air pressure that has been accumulating inside the kiln. How the clay and glaze come out after firing will depend on how much oxygen is present in the kiln. The heat is forced to spread across the whole chamber as the pressure within the kiln increases.

Therefore, altering the damper will change the appearance of the pottery once it has been discharged. The best course of action is to take a closer look at these processes because they are a crucial component of the gas kiln.

Oxidation and Reduction

An oven will burn in oxidation or reduction depending on the oxygen available. These terms can seem frightening and challenging to understand, but they don’t have to be. Below is a quick explanation of oxidation and reduction:

Burning materials generate heat in fuel-burning kilns during a fire. If adequate oxygen is in the kiln chamber, it feeds the flame.

The flame will look elsewhere for air if there isn’t enough oxygen in the kiln. Metal oxides in clay and glazes contain oxygen chemically—for instance, iron oxide or copper oxide.

If there isn’t any oxygen in the kiln environment, the flame will draw it from the clay and glaze. This alters the chemical makeup of the clay and glaze by reducing the number of oxygen atoms they contain. Reduction firing is used when a “reduction environment” is present in the kiln.

This chemical modification will affect the ceramics’ colour and texture. Glazes and clay that have been burnt “in reduction” sometimes have a more raw, unpolished look.

On the other hand, if enough oxygen is present, the flame will burn. As a result, the clay and glaze do not lose their oxygen atoms similarly. “oxidation firing” refers to burning ceramics in an oxygen-rich environment.

When a gas kiln’s damper is opened, more oxygen is drawn into the kiln by the airflow that passes through it. This results in an oxidizing environment. On the other hand, the kiln enters reduction if the dampers are closed, which reduces the oxygen flow. Thus, the functioning of a gas kiln can employ either oxidation or reduction.

Downdraft kilns

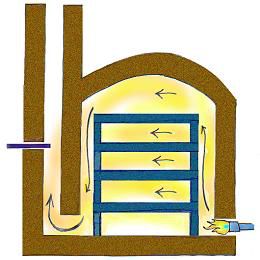

The downdraft gas kiln is a distinct type of gas kiln. Heat enters the downdraft kiln at the base through gas burner ports, the same as the updraft kiln. A downdraft kiln doesn’t have a vent at the top like an updraft kiln.

The heat must once more descend since there is no way for it to leave the peak. The hot airflow heats the pottery twice as it is dropped into the kiln chamber. Because of this, updraft kilns are regarded to be less effective than downdraft kilns.

A downdraft kiln’s flue is located close to the kiln’s base. The airflow is driven down when it leaves the kiln through the low-level duct and enters a chimney. The chimney expels the heat, fumes, and gas that the kiln produces.

Like updraft kilns, downdraft gas kilns frequently include a “sprung arch” construction. Sprung arch kilns have an arc-shaped top, straight sides, and a straight base. An iron angle then supports the walls of the kiln. The entire structure is then covered with an iron jacket, which supports and protects the chamber.

Formally, a springing arch kiln resembles a loaf of bread cut in half. The curved arch was made from bricks with tapering ends. The degree of the curvature will also depend on how tapered the bricks are.

The door is on the front of gas kilns, meaning most of them are front-loading. These doors offer alternatives for hinges. But they can also function on their own. If they are free-standing, they are positioned and secured to the kiln before it ignites.

Electric Kilns

However, electric kilns were only recently developed. Despite being relatively new, electric kilns have already gained much popularity. Ceramic and pottery makers appreciate them much, as do small businesses and hobbyists.

They are often used because they are inexpensive, simple to put up, and simple to operate. Some electric kilns require direct electrical wiring to a power source. It is possible to connect additional electric kilns to a residential electrical supply.

An electric kiln’s inside is coated with refractory brick insulation, just like gas kilns are. A stubborn substance insulates and resists extreme heat.

On the other hand, an electric kiln produces heat using metal coils. These metallic components, or coils, are arranged in groves that have been sharpened into the brick wall. Because the ingredients are powered by electricity, the metal coils warm up.

Because they get softer as they warm up, the elements are positioned around the side of the kiln. Around 1800F (982C), the parts begin to deteriorate, making them useless for use on the roof of the kiln.

Kilns for manufacturing glass are made to work at temperatures below 1700°F (926C). As a result, the roof of glass-burning kilns will include components.

The kiln chamber then starts to warm up. Digital kiln controllers are now widely used to operate electric kilns. These allow you to ramp the kiln utilizing a well-planned fire sequence. After getting the hang of the controls, you may set the kiln to “do its thing” and walk away.

While fire, all kilns need to be monitored, even if electronic kilns may be automated. A burning kiln should never be left alone.

Kiln Sitters

Some other older electric kilns include a control called a “kiln sitter.” A kiln sitter is a partly mechanical device that uses a pyrometric cone. These ceramic bars are specially made to bend when heated. Depending on the temperature, cones will flex differently.

As the kiln warms up, the cone begins to bend. When the cone turns sufficiently, the kiln sitter is designed to shut the kiln off. Once the kiln reaches the proper temperature, the cone will have enough bent to trip the off switch.

Oxidation Firing

Electric kilns don’t require an oxygen supply since they don’t burn fuel. A complete draft is not necessary since oxygen is not burnt. Additionally, oxygen is not supplied to the kiln or used for combustion. As a result, an “oxidation environment” with a lot of oxygen is what electric kilns work in.

An oxidation or reduction fire involves different chemical reactions for clay and glaze. As a result, there is a noticeable difference between the colour and texture of pottery fired in these two environments. For instance, if copper is present in a glaze, the reduction will cause the ice to turn red. However, the same glazing will turn green in an oxidizing environment.

While firing, an electric kiln delivers substantially more dependable and consistent results. Additionally, colourful glazes burned by oxidation have a propensity to shine brighter.

Ventilation

There are no updrafts or downdrafts in electric kilns. However, specific ventilation systems require ventilation since they depend on producing a draft. Ceramics fired during the firing process leak moisture, gases, and fumes. For this, the kiln must be ventilated.

In the conventional sense, an electric kiln lacks a chimney. On the lid of specific containers, there is a venting hole with a bung, though. Some feature peepholes on the side in place of a hole in the top. The spy holes, also known as peepholes, give the potter a glimpse of the kiln’s inside while it burns. Nevertheless, they are occasionally employed to provide ventilation while firing.

The cross draft arrangement is a straightforward ventilation system. There is an open window next to the kiln. Additionally, the kiln’s heat and gases are expelled via a fan.

Other, more effective venting methods place a vent on or close to the kiln to expel the gases. These devices occasionally remove gases and moisture from the kiln’s bottom—a similar technique for venting downdrafts. Overhead vents are placed to drain water and gases from the top of the kiln.

Electric Kiln Designs

A front door with hinges is a feature of some electric kilns. These are front-loading kilns, as the name suggests. A movable top on other kilns allows it to open upward like a freezer cabinet. These are top-loading kilns, as the name suggests. The size and capacity of electric kilns can vary substantially. They might be the size of a desktop kiln or as large as a refrigerator.

Final Thoughts

Today, potters may choose from a wide variety of historically significant kilns. It would almost be unfair to refer to them all by the same name because they are so unlike. Consider the differences between a regular sawdust “kiln” and a continual industrial production kiln.

Even though they are utterly unlike one another, they both try to burn clay. You can be sure to discover a fire technique that works for you, given the wide variety of kiln types available.

FAQ

-

What are the many kiln types?

The two main categories of kilns are intermittent and continuous, insulated boxes with precisely regulated interior temperatures and atmospheres. Only the core area of a continuous kiln, also known as a tunnel kiln, is directly fired.

-

How is pottery fired in a kiln?

Glass is frequently the material that requires the lowest temperatures. Consequently, a ceramic kiln with a high, medium-high, or medium-low temperature range would be excellent for ceramic and pottery production. Additionally, it’s crucial to choose a kiln with a higher temperature capability than what you’ll require for your work.

-

Which kind of kiln do I require?

Purchasing a kiln that can burn hotter than you require an excellent idea. Purchase a kiln rated for 1700° F if you are burning glass at 1500° F. Buy a cone ten kiln if you fire ceramics at that temperature. Heating components use less energy as they get older. just like kilns if you are wondering which pottery wheel to buy for making stunning pottery pieces then this guide is written for you.

-

What distinguishes a glass kiln from a pottery kiln?

Glass kilns typically heat one layer from the top, but ceramic kilns heat numerous layers from the side. This is the primary distinction between the two types of kilns. Because most glass projects are typically relatively flat, glass kilns were created to heat the top

Being associated with art and craft field since decades as a hobbyist and life long learner has given me an opportunity to learn many new things related to art, craft, paints and pottery which i am trying to share with your guys on this website. I have expertise of being professional painter and potter for the last 20+ years

I have learned mind blowing cool tips and insights which makes me a person with ability to improvise and come up with creative ideas and solutions to make stunning and impeccable art pieces of all types which are adored by people across the globe on this website and other platform.